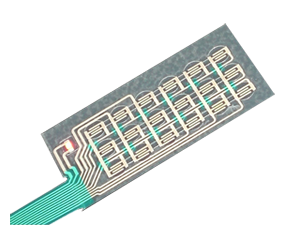

Membrane keyboards were created from the need to have an application range that was greater than the one provided by traditional mechanical keyboards.

The materials membrane keyboards are made up of are more resilient to chemical agents, thereby providing a greater protection against dust and humidity. So it is possible to use this technology on CNC machines, electrical appliances, electrical and electronic devices, even if they are subjected to heavy-duty applications.

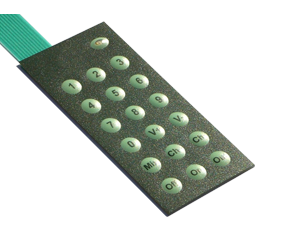

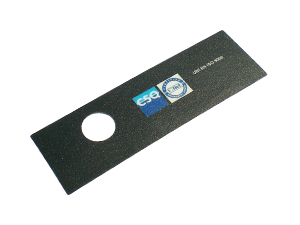

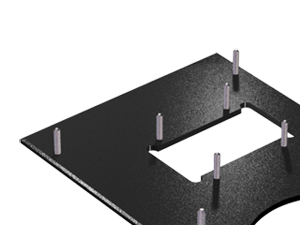

Thanks to the opportunity of producing them in a wide variety of shapes and colours (with raised keys, see-through windows, built-in LEDs and metal caps), they can be used in cases where design is an integral part of the product.

Features

-

Resilience to chemical agents

-

IP protection

-

Antimicrobial

-

Customisable shapes and colours

-

Raised keys

-

See-through elements for the display

-

Metal caps

-

Built-in LEDs